(I just realised I never got around to posting externally this article from my Atkins internal blog on my external one - so here it is! These are the words and some slides for a talk I gave in April 2012 at the ICE to ACED - the Heads of Department for the UK's civil and structural degrees. Por Ray Purvis also presented, as did Costain. You can see the full slide deck at http://www.jbm.org.uk/uploads/ACED_Atkins_John_Roberts.pdf)

Assets in the built environment: How it was

o The client wrote something

o The designer drew something

o Contractor A dug something

o Contractor B poured something

o Contractor C bolted something on

o The client paid the utility bills

o Contractor D added some stuff

o One day it got knocked down

These were separate activities by separate entities, carried out in a potentially adversarial contractual atmosphere. At each step there was a loss of data and inefficiency crept in.

We are now moving towards a nirvana that has been talked about for a decade or so now, but now we are starting to smell it, see it and are almost touching it. Instead of the old process we move to one where there is a clear flow of data through the project, being added to, evolving, refining and eventually being usefully delivered to end users, informing and supporting the lifetime use of the asset.

This flow of data is one key way to achieve the key aims of the Government's Construction strategy. It is a key step towards improving the performance of the government estate in terms of its cost, value and carbon performance: "the purposeful management of information throughout the lifecycle of an infrastructure project”. BIM becomes is the key vehicle for information on its journey through the project lifecycle in a managed process.

So let's think about the key abilities and behaviours all team members are going to need when working with information on this journey. Two key aspects are going to be:

o Understanding data management

o Ability to work within a virtual environment

In fundamental terms all our team members need to understand how to receive or source data, use or develop data and then finally issue or archive data.

Let's think about civil infrastructure projects - as there is much more diversity in its data formats than for building projects. When starting a project the simple phrase 'survey' has been replaced by an increasing range of geomatic data types, file formats and all sorts of geospatially related information.

Understanding what you have got and what you can get is a key first step for any project. It is also vitally important to understand the level of reliance you can place on received data. It is easy to fall into the trap that digital data is accurate to multiple decimal points. Since this information is about to become enshrined in everything that follows it is important that engineers know the issues to question about data accuracy.

Next new data gets generated within that context. At the moment that is mainly the model data that we use to generate our 'drawings', but generation of, or linkage with, our analysis, programme, cost and carbon data is now all feasible and adoption is mainly limited by the speed our teams are able to incorporate multiple parallel innovations into their standard practice. A key skill will be how data sources can be combined to efficiently generate optimised designs.

And once a design has been developed that information needs to be issued and be suitable for its legacy end use. When we just issued paper drawings to a contractor we didn't need to anticipate how the end user would once day be interfacing with that data. BIM is going to require our designers to understand much more about our client's future needs.

So you can see that one of the key requirements of BIM is that team members understand how to manage data on this journey. Data sources, file types, data reliability and the way it can be combined are all key issues that engineers must understand to make sure a project's information journey is successful as it passes through their hands.

Alongside that it is vital that all team members are able engage in a collaborative 3D virtual project environment. I have great hopes that that BIM is going to reverse a fragmentation that has crept into the industry with CAD.

Once upon a time design offices were places with big drawings boards where everyone could see how the design was developing over the days a drawing took to produce. It was naturally a social, collaborative environment and experienced eyes naturally saw everything going out of the office.

The CAD-based office at its worst has been a very different animal. Potentially you have the Nintendo generation all focused on their own small screens. The team of engineers are each looking at a series of unrelated analysis models. Meanwhile a separate CAD team are working on unrelated 2D plans and sections. This is not a naturally collaborative diagram.

If we get it right the BIM-enabled design team could look like this. Design, analysis and delivery teams all looking at a single shared version of the truth. We're not there yet as an industry but this is an implicitly collaborative diagram.

Our ability to move to this way of working is based on all our team members being able to engage in a 3D virtual project environment. They need to be able to conceptualise, scheme, analyse, review and deliver in that environment. If you can't work in 3D you will effectively be locked out of the project.

A final thought about interfaces and design management. Once upon a time kids played with wooden blocks. They were loose fit, but if you were careful and didn't knock them over you can lots of fun building stuff.

Then there was then an unrelated series of technology changes enabling highly accurate plastic injection moulding. A Dane invented an interface standard that remains unchanged to this day.

Now, it always feels that new rules are going to tie your hands and stifle creativity. However that is evidently not the case with Lego. There are now a huge variety of block types and colours and you only have to go to Legoland to see that that interface standard has allowed a toy to move well beyond what could be achieved with mere wooden blocks. I was proud to see my Canary Wharf Station roof there two weeks ago - fame indeed!

So, why am I telling you this? A technology change has triggered as similar revolution in the way the building blocks of design data fit together. The best run projects have always been the ones that implement best practice design management. Our Lego standards are BS1192, BIM execution plans and a planned delivery process.

Of course, management of these interfaces actually isn't new. If you are good you are naturally doing all this already.

o Ray and I call it design management

o Costain might call it construction management

o The operator would call it facilities management, and

o The client might call it asset management

The only thing that BIM changes is that you absolutely can't get away with ignoring the issues about how your work relates to the overall project. It is no longer good enough only for your technical work to be technically excellent. Introducing your wooden block into a Lego project will not work. Your work needs to be delivered to BS1192 and project standards and your data has to be reliable and reusable by the other team members who will rely on it. BIM requires us to be much sharper on our Design Management.

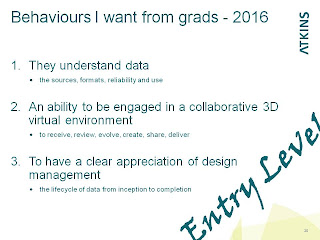

So, it is now 4 years time. You are delivering this year's batch of 4-year course Masters students to the industry. It is 2016 and the Government's Construction Strategy has provided the catalyst for the whole of UK construction to be at or above Level 2 BIM. 2D AutoCAD is dead. Why am I going to employ your graduates?

Why I'll employ a grad in September 2016:

o To understand data

· the sources, formats, reliability and use

o An ability to be engaged in a collaborative 3D virtual environment

· to receive, review, evolve, create, share, deliver

o To have a clear appreciation of design management

· the lifecycle of data from inception to completion

If you can give me that I'll be happy. At one level I think this is quite a simple list of 'new' requirements.

Note however, this is isn't an 'expert' list. These are not PhDs from your new department of BIM. This is not Ray's new BIM team. This is 'entry level' for grads. This is right alongside wl2/8. If they don't have the potential for working this way there isn't really a place in the UK construction industry for them.

They will be wooden blocks in a Lego world.